ProFlow´s deep dive into warehouse automation: Geek +

Interview series

In 2022, we will do an automation focused interview series at ProFlow. We are talking to some of the major traditional European players, but also to the new players who are investing 100% in robotics and alternative solutions. We see that both types of automation can work together but also compete, and we want to help our customers to monitor this development and, if necessary, propose it.

We talk to automation suppliers and robot suppliers such as TGW, Knapp, SSI Schäfer, Swisslog, Geek +, Element Logic, Kardex, Ferag, Dematic, Caja! Suppliers have so much knowledge, the development is going at an intense pace and we hope that this interview series will give you as much as it has given us!

”Right now the automation sector is booming, we are looking forward to expand ourselves in different regions in Europe. In the Scandinavian market, we’re working with different sales agents, distributors and soon also with customers.”

”Education is a big part; we are here to show the market that robots are the future. The solution that we provide is really good and also very interesting from a ROI perspective. We want to convince the customer to change their traditional automation system to new flexible robot system.”

”We develop new robots with new technologies inside the robots. The robots can be with laser sensors, like 360-degree sensors, but it is the software that guides the robot and tells them what must be done. All our R&D is related to software.”

”We can see on the market that facilities tend to have 10-12 meters height capacity for implementing an automated solution. Before we used 3 meters high, ground floor shelves, plus mezzanine. Naturally, we develop a solution that avoids the mezzanines, so now we have higher shelves with higher density.”

”We actively work on the environmental impact of our products. We want to show our robotic systems can support making a facility more sustainable. Topics like reducing energy consumption, ergonomics, and optimized processes are at the core of our focus.”

”The systems that we provide to our customers are very flexible and easy to install to an already existing facility. We are doing the installation and implementation very fast, the maximum timeline in our projects is 25 weeks from order to installation.”

Geek+, founded in 2015, is an intelligent robot company shaping the smart logistics revolution. At Geek+, we develop autonomous mobile robots (AMRs) that handle various tasks, including picking, moving, and sorting. Geek+ have implemented several installations already with more to follow in 2022.

We have spoken to Jean Gateau, international sales director, who takes care of Geek+ deployments of different solutions all around Europe: ”Right now the automation sector is booming, we are looking forward to expand ourselves in different regions in Europe. In the Scandinavian market, we’re working with different sales agents, distributors and soon also with customers.”

Where lies the biggest potential and what is the easiest process to automate?

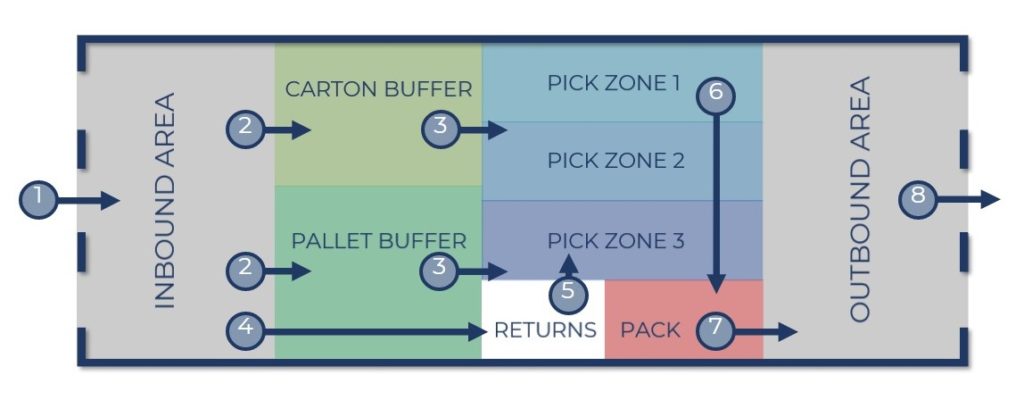

Flow number 1 and 9 depends on if it is or if it is not a crossdocking business case. If it is a crossdocking business case we can implement moving robots, placing the inbound pallet from the inbound area to the outbound area. If it is not a crossdocking the robot places the inbound pallets in picking zone or pallet storage.

If it is the scenario that I see in the picture I will exclude flow number 1 and 9 directly because they will need to go through the other flows.

For the carton buffer we could do something for flow 2 and 3. For the pallet buffer we could do something for flow 2 and 3 but it will take some time to develop and set up processes.

For the picking zone A, B and C we can implement something fast and have fast or good efficiency, the same for the flow 4 and 5 (returns) we are very efficient. For picking we have classical mobile share solution, shuttle system with high density that can be interesting for those kind of business cases.

For the crossdocking area: If it is pieces I will say yes, if it is baskets or cartons it depends on how the process is organized inside the facility. It might be that installing a system would not be interesting from an ROI point of view. However, there are always options that can be discussed and then integrated into the facility.

For the sorting area we have sorting robots. Small robots that place parcels from a feeding station and shoot them in different shoots corresponding to the station. This is a real return of investment. We have one customer in Spain where we reach roughly 9000 parcels/hour with 260 robots. 1 robot costs roughly 6 000 EUR, so compared to traditional sorters we can compete easily and it’s more flexible.

Let’s say you have a customer that need to increase their automation level, where should they start?

Definitely picking and sorting, especially in western European countries, those are good areas of automation to start with upgrading.

Can you mention three success keys that makes the project successful?

The first thing is to understand that if you change to robots – how can you integrate robotics inside the existing facility without changing everything. Second, the ergonomics: to avoid pain for the workers and then to avoid touching the SKU ten times while you can do it two times.

The last point is how you can guarantee the good interaction between the automation system and the human operator. In our system, you don’t need to push a button (like other automation-systems) and everything is done. Our system provides an interaction between the robotic system and the humans.

If you were a customer and evaluated different suppliers, which criteria should you recommend a customer to look most in to?

The grows of the business, the investment and understanding, if you can implement the system in the exciting facility.

If you investigate your portfolio and if we limited it to Europe, do you have a best-selling product right now?

Yes, it is our mobile share picking solution. P500- and P800-series are our bestselling products. But to clarify, we are selling more software and end-to-end installation than products.

In what way are Geek+ most innovative or unique? Do you have a special product group or something that you want to highlight?

The most selling products and which we are most confident with are the picking and sorting solutions. We are heading more to high density storge like RS5, RS8, robot shuttle systems, to expand the range of applications. It is important to understand that in China and all around the world, Geek+ are buzzing new innovated hardware solutions that we can provide on market.

Which product are you most proud of?

The picking solution! It is in the picking- and sorting area that we are investing most R&D resources. We develop new robots with new technologies inside the robots. The robots can be with laser sensors, like 360-degree sensors, but it is the software that guides the robot and tells them what must be done. All our R&D is related to software. As you can see, we have new products, new items, new devices and the software is continuously being developed based on the different innovative equipment that we propose to the market. Even if the robot places the totes on the conveyor, after all there will always be a human that will be picking items from the tote.

Do you just use information from the internal warehouse and take inputs from the surroundings to feed your algorithms? Or are you just looking within the warehouse, the patterns, orders and so on?

No, it is mainly in our equipment’s, it is not related to facility. WCS is a software that control the optimisation of the SKU inside the zone and RMS is the fleet management that optimize the number of robots and the route for the robots inside the zone. Those software’s are mainly related to the equipment’s that we provide directly and not related to new facility. We don’t take any data from the facility except of course the space, the area, the height and so on. It’s not related to facility because otherwise as you can imagine, it will take much more time.

When you look at a warehouse, which is the least developed area in warehouse whit in automation?

Last year we developed solutions that provides systems where we can densify the SKU storage. High density for the storage of SKU inside the zone to increase the number of SKU and the efficiency, plus improving the picking efficiency with better ergonomic.

We can see on the market that facilities tend to have 10-12 meters height capacity for implementing an automated solution. 2-3 years ago, we used the space for mobile share picking solutions with maximum 3 meters high shelves on the ground floor plus mezzanine. Naturally, it came to our mind to develop a solution that avoids the mezzanines, so now we have higher shelves with higher density.

Can you rank the sort of solution that you are competing with?

The main competitors on the market right now are focusing on mobile share solution and sorting robots, and typical mobile share picking solutions without AI but still alive on the market. In addition to that, other Chinese companies are coming up in the European market.

You have mainly mentioned other robot companies as your competitive, do you also se traditional warehouse with a lot of conveyers as competitors?

I don’t see them too much as competitors because in a facility we will always need conveyers. One reason is because of the price. Even if you can replace one conveyor-flow with a robot-flow, we will still need 3 robots to do the flow of one conveyor and the investment will be four times more. So, at the moment I don’t see the conveyor companies as competitors, more like partners.

What is your view on the impact on the environmental questions regarding automation?

It’s a subject that we are actively working on. We want to show how our robotic systems can support making a facility more sustainable. Topics like reducing energy consumption, ergonomics, and optimized processes are at the core of our focus.

Which is the best automation fair in Europe, according to you?

LogiMAT in Germany, SITL in France.

How to learn more about automation?

In the facilities directly = site visits, operational and of course, we have several sites where we can do visits. For picking and sorting solution we have several ones is in France, Germany, Spain and Poland.

Who is your dream customer?

The dream customer for me is a microprocessor manufacturer which has 75 000-100 000 SKU, handling mainly small pieces, doing distributions with an e-com flow so they are looking for high efficiency in terms of picking, so not only a manufacturer. That means that we can increase the number of robots. The smaller the SKU is, the easier and faster is the picking process and you can increase the efficiency. That is pretty much the dream customer for me, its related to the SKU – a lot of SKU but the size would be small.

How would your dream automation solution looks like?

I know the future automation is to get the smallest automation system you can get. All business warehouses are mainly storage, even in cross-docking they still need to store. So, reduced space is the best solution for any customer.

Is it anything else that you want our customer or reader to know about Geek+?

Geek+ is growing fast and we expanded in different markets in order for us to increase our deployment in the European market. The systems that we provide to our customers are very flexible and easy to install to an already existing facility. Plus, we are doing the installation and implementation very fast. The maximum timeline in our projects is 25 weeks from order to installation.

When you look at traditional sorters, that can go up to 40 000 parcels per hour, of course you need a big facility. According to the researches I’m doing, I can see that they tend to go for robotics, but it is still the traditional sorter that has an advantage because in several areas robotics is still new and an unknown territory. So we are working together with customers and explain them exactly where the advantages are in the long run and in that way gain their trust.

We are here to show the market that robots are the future. The solution that we provide is really good and also very interesting from a ROI perspective. In some business areas customers are not there yet but they will be in the coming years.

For the picking solution, the traditional human picking is still very popular even in western European countries. It’s hard to change everything in the facility from the human picking process to automation but we are starting to see an increased interest and a change of the mindset.

Traditional automation systems like mini loads and robot shuttle systems are still elemental but customers are looking at more small and flexible solutions to implement. Solutions that can handle some flows that are challenging to take care of because they don’t have the efficiency, that we can achieve. Sometimes we really need to convince the customer to change their traditional automation system to new flexible robot system. Education is a big part; it takes time because many logistics companies are at the beginning of their automation journey.